Detection of Foreign Bodies in Foods by Metal Detector

A foreign body is any material such as glass, wood, metal, plastic, stones, or any material of animal origin like insects which must not be there in the food products. The consumer does not want these types of foreign bodies in the food as they can badly harm the end user/consumer.

There are many methods to detect and prevent these foreign bodies from going into end products, like foreign body detection through sieving and filtration which is often used for powder-type and liquid ingredients.

Foreign body prevention and detection is an important element of food safety and must always be ensured to safeguard product contamination. Other methods include foreign body detection in foods by metal detection which is an excellent method and is being used in many food industries to detect and prevent foreign bodies. Further detail of foreign body detection in foods by metal detection method is given below.

Principles of Metal Detection:

The most common design of metal detectors uses a ‘balanced coil’ system. This system comprises an

encircled coil arrangement that generates a magnetic field. When metal passes through the coil,

the magnetic field becomes disturbed. The signal created by this disturbance is amplified and used

to detect the presence of metal within the product.

A second type of detector is the ‘Ferrous in Foil’ detector. This uses magnets in the search head and

is capable of detecting ferrous metals and magnetic stainless steel within products packaged into

aluminum packaging.

Metal Detection System Location:

Metal detection inspection systems should be located at the end of the product packaging process,

or as close as possible to the finished packing point and in line with the main production flow.

Systems should be specified in conjunction with the equipment supplier to ensure they can perform

effectively in the intended working environment. Performance should not be adversely affected by

external electrical interference or by plant operating conditions – e.g. wet environments, areas of

high vibration, extremes of temperature, or harsh hygiene procedures.

Metal Detector Types:

There are many types of metal detectors available. The most common types in use include:

Conveyor Mounted Systems Metal Detectors

These metal detectors are used for wet, dry, frozen, or fresh packaged or loose products

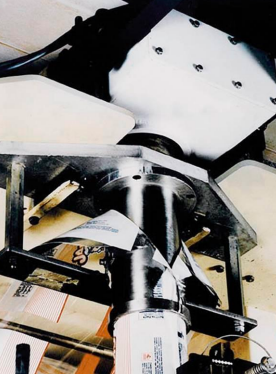

Vertical Packaging Systems Metal Detectors

These metal detectors are used for free-falling products immediately before the final packaging of these products.

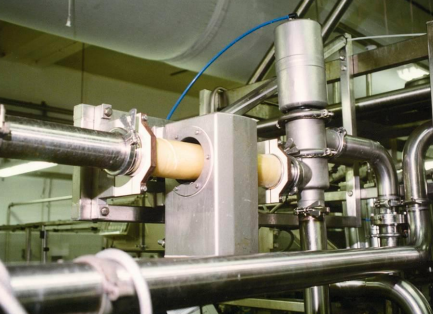

Pipeline Systems Metal Detectors

These metal detectors are installed inline for liquids, slurry, and paste products like tomato ketchup, etc.

Metal Detector Sensitivity Standards:

As metal detection of finished product packs is classified as a critical control point in the food safety management system HACCP plan, the critical limits must be set to achieve optimum sensitivity. Optimum sensitivities must be established and set for each product or product type.

The sensitivity of the detection system must be maximized to the optimum level, however, this

should not result in instability where the effects of product/environment cause false rejections.

Sensitivity Values for Conveyor-Mounted Metal Detectors

The followings are metal detector sensitivity guidelines for conveyor mounted metal detectors.

| Product Height | Ferrous (mm) | Non-Ferrous (mm) | Stainless Steel (mm) |

|---|---|---|---|

| Up to 50 mm | 1.0 | 1.2 | 1.5 |

| 50 mm – 100 mm | 1.2 | 1.5 | 2.0 |

| 100 mm – 150 mm | 1.5 | 2.0 | 2.5 |

| 150 mm – 200 mm | 1.8 | 2.2 | 3.0 |

Sensitivity Values for Vertical Packaging Metal Detectors

The followings are metal detector sensitivity guidelines for vertical packaging metal detectors.

| Product Height | Ferrous (mm) | Non-Ferrous (mm) | Stainless Steel (mm) |

|---|---|---|---|

| Up to 100 mm | 1.0 | 1.2 | 1.5 |

| 100 mm – 150 mm | 1.2 | 1.5 | 1.8 |

| 150 mm – 200 mm | 1.5 | 1.8 | 2.0 |

| 200 mm – 250 mm | 1.8 | 2.0 | 2.5 |

When testing vertical packaging lines, ferrous, non-ferrous and stainless steel test pieces

should be independently placed in the product flow.

Sensitivity Values for Pipeline Metal Detectors

The followings are metal detector sensitivity guidelines for Pipelines metal detectors.

| Product Height | Ferrous (mm) | Non-Ferrous (mm) | Stainless Steel (mm) |

|---|---|---|---|

| Up to 50 mm | 1.5 | 2.5 | 3.0 |

| 50 mm – 100 mm | 2.5 | 3.0 | 4.0 |

FAQ