Allergen Cleaning Strategies and validation of allergen cleaning

Allergen management is one of the fundamental requirement of any Quality & food safety management system. Also as per each country regulatory requirements all food processing sites must declare allergens on the product label if present in the food.

Since Allergen Cleaning Strategies and validation of allergen cleaning is extremely crucial, today we will be discussing Allergen Cleaning Strategies and validation of allergen cleaning in food products during during manufacturing of food products.

Objective- Allergen Cleaning

The four main types of food soil found on processing equipment are categorized based on their macroconstituent makeup, such as carbohydrates, fats, minerals, and proteins. These soils are often complex and made up of various components. Food proteins, including allergenic proteins, can be particularly challenging to remove, especially when they have been heat-treated and have stuck to surfaces in contact with food.

When specialized equipment and processes for specific allergens are not available, a cleaning protocol is necessary to effectively remove the allergen from the equipment to prevent cross-contamination. Cleaning shared equipment or processing lines to remove allergens is a crucial aspect of controlling allergen cross-contamination.

Scope-Allergen Cleaning

Allergen cleaning programs must be implemented for all equipment and processing lines when there is a change in the allergen profile to effectively prevent cross-contamination onto the subsequent product.

Efficiency of Chemicals in Eliminating Allergenic Proteins

During selection of chemicals for allergen cleaning, sites must consider their process first and then based on the products and allergen present in the products, must select appropriate cleaning chemicals. Below is efficiency of cleaning chemicals being used in allergen cleaning programs globally in food manufacturing.

| Chemical Type | Efficiency |

| Alkali/Caustics with H202 | Great at eliminating protein films. The oxidizing agent aids in dissolving the soil. |

| Acid | Ineffective when used alone on proteins. When acidic detergent cleaners are required to remove mineral buildup, the equipment must first be cleaned with an alkali detergent, as acidic cleaners can cause protein soils to stick to surfaces and become hard to remove. |

| Detergents/Surfactants | Assists in removing difficult-to-dissolve dirt through wetting the surface and then using a cleaning solution for dispersal. |

| Caustics | great solution at removing protein films. |

Allergen Cleaning Strategies

Allergenic foods and ingredients can come in various forms such as solid, liquid, paste, particles, or powder. It is suggested to use separate tools for handling and cleaning different allergens and avoid reusing them. Additionally, it’s suggested to have a process in place for cleaning and inspecting tools to ensure they are clean.

Based on the food and process equipment’s, one of the following strategy can be adopted for allergen cleaning.

Dry Cleaning:

Dry cleaning surfaces can be done through methods such as brushing, wiping, or vacuuming. However, using air hoses is not recommended as it increases the risk of spreading allergens. For allergens that are dry and have little to no oil content, dry cleaning is suitable. It’s important to ensure that any tools used to clean allergens, such as a vacuum cleaner, are thoroughly cleaned and confirmed to be free of allergens after use to prevent cross-contamination.

Wet Cleaning:

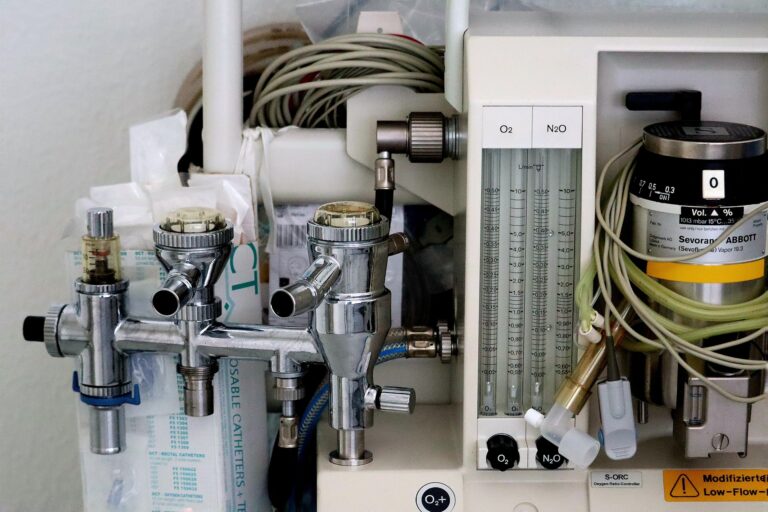

This process typically uses water and may also include chemicals. The method of cleaning chosen depends on the properties of the food being processed and the equipment being used. Wet-cleaning methods can be classified into various categories as below:

- Wet Cleaning- Clean-in-place (CIP):Cleaning where equipment does not need to be disassembled, and the cleaning solution can be reused (although the water and cleaning chemical should not be recovered because it may contain allergens and could cause re-contamination if reused)

- Wet Cleaning- Clean-out of place (COP):Cleaning where equipment can be taken apart partially and cleaned in tanks.

- Foam or gel cleaning: Cleaning where the chemical is applied as a foam or gel to the equipment that increases the duration of contact with the dirt.

- Manual Cleaning: Cleaning where equipment is completely taken apart and cleaned manually.

Once allergen cleaning is done , each food manufacturing site must ensure the followings.

- Ensure that food contact surfaces are sanitized to meet hygiene requirements

- Ensure cleaning checks have been carried out to ensure all food contact surfaces have been cleaned and allergen residues free

- Ensure cleaning tools are properly cleaning and placed on their dedicated place.

Validation of Allergen Cleaning Programs

Validation of an allergen cleaning regime in food processing lines is extremely important to make sure that lines are allergen free after the cleaning and sanitation, it is also a great tool to see food processing sanitation effectiveness.

Validation of an allergen cleaning regime in food processing lines involves demonstrating that a specific cleaning procedure can effectively remove allergenic proteins and prevent cross-contamination in food production. This is achieved through measuring the effectiveness of the cleaning procedure through quantitative or qualitative methods and ensuring that allergenic proteins are reduced to an acceptable level, below the limit of detection, to prevent future contamination.

Scope- Allergen Cleaning Validation

Allergen cleaning validation is the process of demonstrating that a cleaning procedure effectively removes allergenic proteins and prevents cross-contamination on shared equipment or lines used to manufacture both allergenic and non-allergenic products. This is done through measuring the cleaning procedure’s effectiveness and ensuring that allergenic proteins are reduced to an acceptable level, below the limit of detection, to prevent future contamination.

Validation of Wet or Dry Cleaning: Direct Surface Sampling

- Allergen validation is performed in a series of three consecutive tests.

- Before beginning the allergen cleaning process (after the production run of allergen-containing products), the product contact surface of the equipment should be swabbed using allergen-specific swabs to verify that the swab can detect the specific allergen (as a positive control).

- In addition to the positive control, a negative control should also be performed by swabbing an area that does not contain the allergen to confirm that non-detected levels are achieved. If the allergen kit includes positive and negative control standards, these should also be tested in addition to the controls

- Perform the allergen cleaning process using a wet method.

- After cleaning, the equipment surfaces must be inspected and found to meet the visually clean standard.

- After the equipment is visually clean, it should be swabbed using allergen-specific detection swabs to test for any remaining allergenic proteins. The swabbing should focus on areas where buildup of food is known to occur, as well as difficult to clean areas, and porous and irregularly shaped surfaces. Equipment that heats product during manufacture should also be swabbed, as burned-on allergenic foods can be hard to clean. A minimum of 15 sampling points per production line across all types of equipment surfaces is recommended. If a CIP (cleaning in place) system is used, samples of the CIP rinse water should also be collected and tested.

- If the product that is run through the line after cleaning does not contain the allergen from the previous run, then finished product allergen testing should be conducted. If the product has the same allergen profile as the product that was run before cleaning, no finished product testing is necessary. A minimum of 3 packages or containers per packaging/filling machine should be tested, including the first product through, and then at set time intervals determined by the speed of the packaging operation, for the presence of the allergen.

- If the allergen swabs and finished product show no presence of the allergen after 3 consecutive cleaning runs, then the cleaning procedure has been validated as effective for removing that specific allergen.

Recommended Technique for Surface Sampling

To ensure consistent results with each test, a consistent swabbing method should be used. When taking a swab, the following should be considered:

- Swab Type

- Number of swabs per area

- The quantity of buffer/water solution used on each swab.

- The method employed to swab the surface.

- The size and location of the surface area being sampled.

- The steps taken to extract the substance of interest from the swab

Suggested Areas for Swabbing

During the initial validation, a comprehensive assessment of the line cleaning can be obtained by swabbing as many locations as possible. Once the cleaning effectiveness has been established, a sampling plan can be developed where fewer points are swabbed for subsequent verifications of cleaning.

Revalidation

Revalidation of the allergen cleaning procedure is necessary to ensure that the cleaning process is continuing to be effective. This should be done at least once a year per production line, or more frequently if there are any changes in cleaning chemicals, ingredients, handling or equipment.